Often found on conveyor systems and chutes use these strips where friction between two parts or materials is wearing down equipment to extend equipment life.

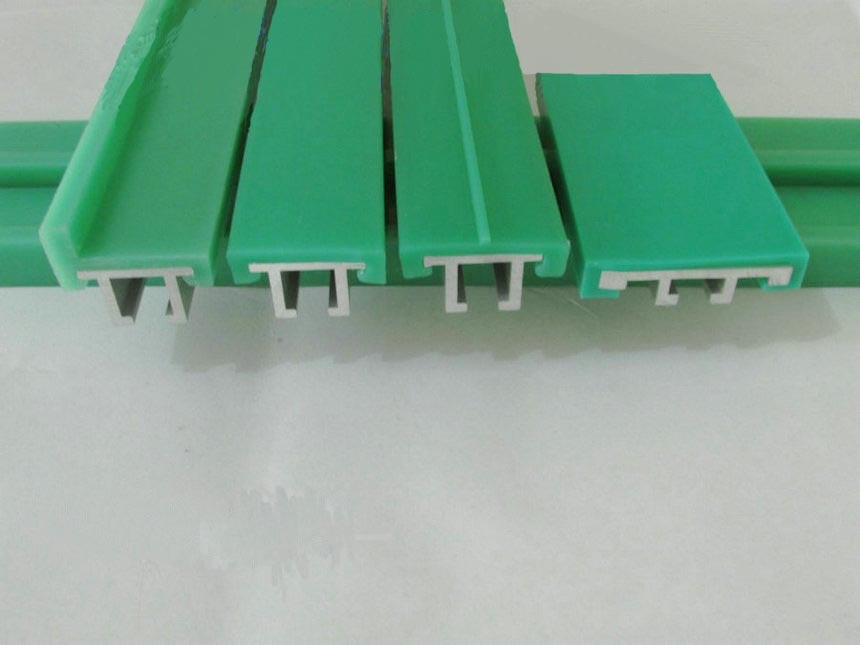

Plastic wear strips conveyor.

About 18 of these are plastic sheets.

Conveyor wear strips.

The plastic wear strips in our conveyor provide the maximum surface area between the chain bars and the plastic over which they slide.

For shorter length requirements cut wear strip is available in 10ft lengths in a variety of uhmw pe materials as well as md nylon and up to 48 lengths in nylon acetal and teflon.

Plastics also reduce wear specifically in the chain pin and bushing by supporting the chain over the full length of the conveyor.

A wide variety of conveyor wear strips options are available to you such as material applicable industries and warranty.

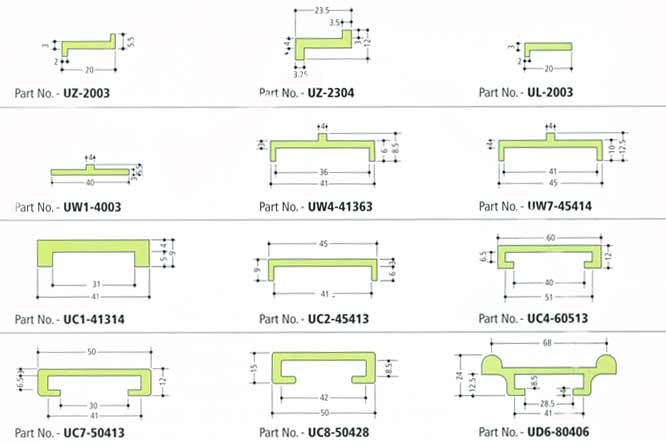

Profile type ck type ckg.

Profile type ckg 14h type ckg 15v.

Conic side guide.

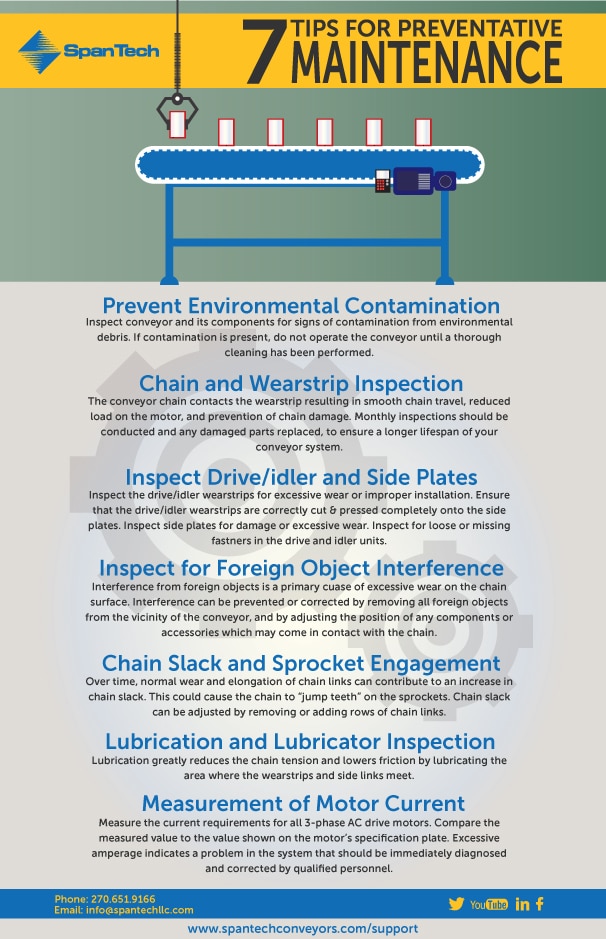

Reducing wear in conveyors.

During this time we have gathered a vast wealth of knowledge which enables our sales staff to assist in the correct selection of both the specific profile required and the best grade of material to meet the demands of the material handling industry in the 21st century.

These rotate freely and are offered in a range of sizes.

Machine supply provides custom plastic wear strip for food beverage such as bakery equipment bottling equipment canning equipment food beverage conveyors cooked food conveyor equipment deboning conveyors food processing equipment frozen foods food packaging equipment meat processing palletizers pizza dough poultry equipment snack food conveyors.

Neck guide wear strip.

Food industry wear plates suitable for food contact these plates are made of fda listed uhmw plastic which has a slippery surface to minimize friction.

Rivets attach plastic wear strips to the conveyor frame.

Chain guide wear strips.

Wear strips sliding supports and guides as well as curved and straight tracks that are extruded or machined are used in many industries and represent an ideal complement to modular belts slat and conveyor chains and timing belts.

Pennine have been involved with the design manufacture and supply of high quality custom plastic extrusions for over 35 years.

In addition we also offer snap on sliding shoes locking collars and serpentine wear strips with corresponding spacers.

Also known as sprocket driven conveyor belting sprockets drive the belt.

Food industry cut resistant conveyor belting.

We offer a range of plastic and rubber coated return rollers to support and reduce the wear on chains and belts underneath the conveyor.