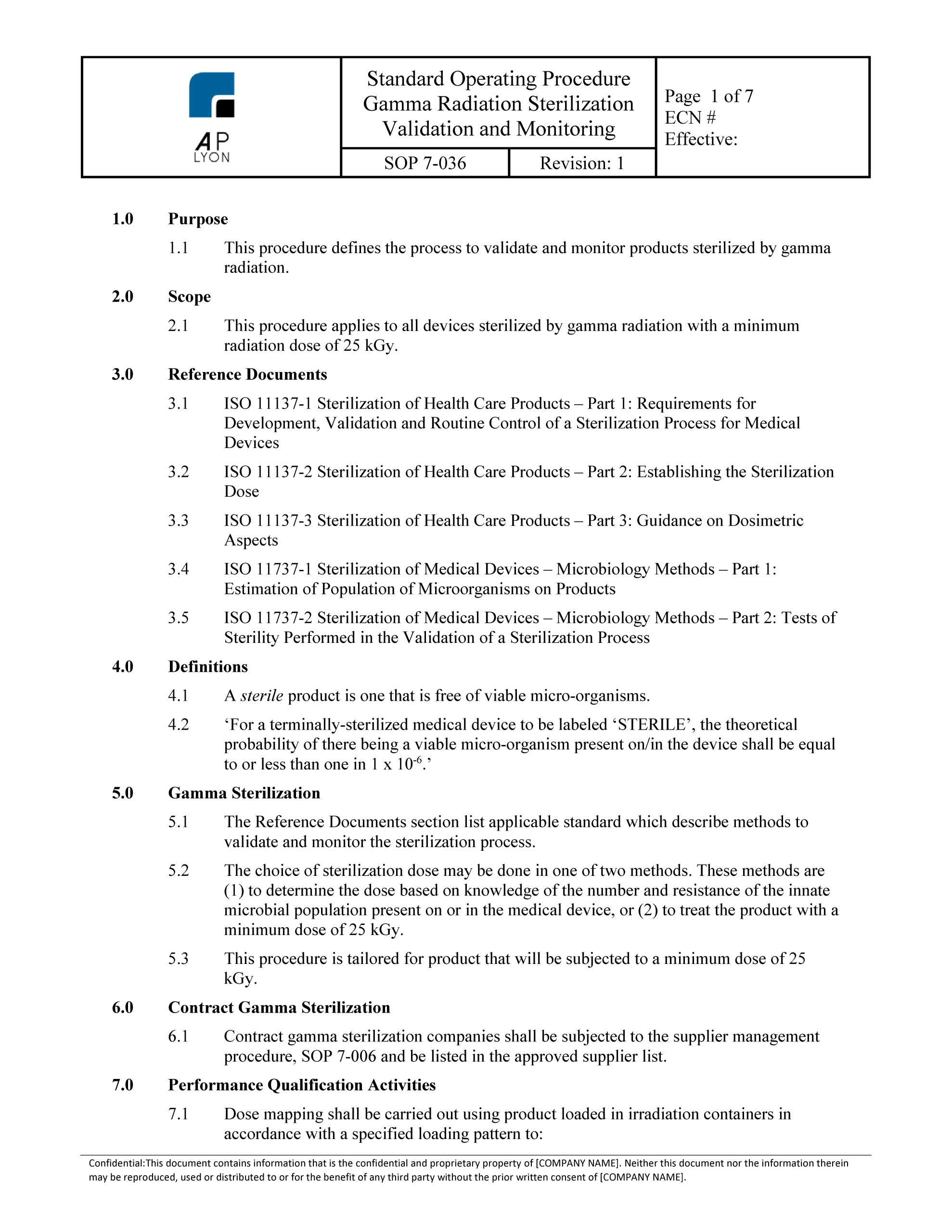

Learn from renowned experts about fda regulations and techniques for effective medical device sterilization ethylene oxide eo sterilization radiation sterilization routine processing iso 17665 gamma sterilizer validation iso 11137 radiation sterilization sterilization process etc.

Medical device sterilization training.

Commonly referred to as biological safety this evaluation of risk consists of the biocompatibility component but also multiple other mechanisms that work together to accurately predict medical device biocompatibility based on individual materials and use.

March 16 2021 march 18 2021.

Level 2 script of the wfhss education group sterilization of medical devices page 6 35 2 1 1 d value d value.

Medical device sterilization trainings through webinars in person seminars standards and best practices.

Firms may elect to comply with these standards.

However compliance to.

The company recently reentered the medical device sterilization market and is manufacturing and selling ethylene oxide sterilizers scrubbers and related accessories.

The validation of sterile medical devices frankfurt 2021.

Steris is a leading provider of infection prevention and other procedural products and services.

Learn more about sterilization methods in the submission and review of.

As a notified body we have a team of qualified and experienced industry microbiologists that can help you navigate the areas of compliance within the areas of.

Items that touch mucous membranes or nonintact skin like endoscopes respiratory therapy equipment and diaphragms require high level disinfection.

Ethylene oxide sterilization is an important sterilization method that manufacturers widely use to keep medical devices safe.

The biocompatibility of medical devices directed by iso 10993 1 is a critical part of the medical device risk management process.

The d value decimal reduction time is the time in minutes that is needed to reduce a population of a particular microorganism by one log level at a given temperature.

5960 heisley road mentor oh 44060 usa 877 783 7479.

Clark s varied background includes extensive knowledge in sterilization technologies finished goods testing business development plant and quality management medical device.

Learn how to achieve more successful testing outcomes by attending nelson laboratories the validation of sterile medical devices.